In today’s fast-paced manufacturing world, precision and efficiency are key. Manufacturers face increasing pressure to produce high-quality products while minimizing waste and reducing production time. At Radmot, we’ve built our reputation on consistently delivering high-precision CNC turned parts while maintaining strict adherence to international quality standards.

With a focus on statistical process control (SPC) and state-of-the-art technology, Radmot stands out as a leader in the production of CNC turned parts for a wide range of industries. Our dedication to zero rejects, cost-effective solutions, and high-quality results is what separates us from our competitors.

Commitment to Precision: Statistical Process Control

At Radmot, we pride ourselves on our meticulous attention to every detail of the production process. The backbone of our success lies in our commitment to statistical process control (SPC). This advanced quality management tool ensures that our manufacturing processes are consistent, controlled, and optimized to produce zero defects.

SPC is integrated into every aspect of our operation, from the careful selection of machine tools to the monitoring of production parameters. By using SPC, we can continuously monitor the production process in real-time, identify any potential issues before they become problems, and make the necessary adjustments to ensure the highest quality output.

Our SPC system is fully integrated with our measuring machines, allowing us to conduct rigorous testing and quality control checks throughout the entire production process. This means that at every stage—from raw material input to the finished product—our parts are measured against stringent quality standards to ensure precision and accuracy. As a result, we can confidently guarantee that our customers receive flawless parts every time, with zero rejects.

Expertise in CNC Turned Parts Production

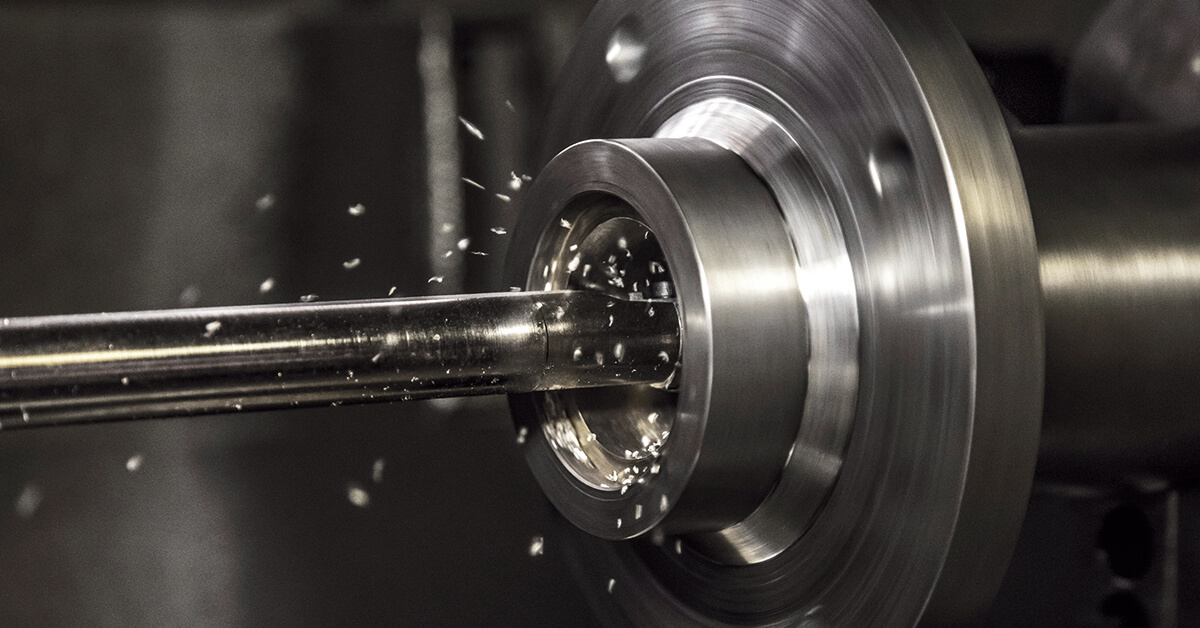

Radmot specializes in the production of CNC turned parts, catering to industries that require precision, efficiency, and reliability. Our production capabilities are vast, allowing us to produce parts with diameters ranging from 6 mm to 250 mm and lengths up to 680 mm. Whether you’re in need of small, intricate components or larger, complex parts, Radmot has the expertise and equipment to deliver.

Our team of highly skilled professionals uses the latest CNC technology to ensure that every part we produce meets the exact specifications required by our clients. We have the ability to produce large quantities of high-precision parts while maintaining strict quality control, making us the go-to solution for businesses that require serial processing at the highest standards.

Cost-Effective Manufacturing Solutions

One of the key advantages of working with Radmot is our ability to provide cost-effective manufacturing solutions without compromising on quality. We understand that businesses need to keep costs down while maintaining the highest standards of precision, and we are committed to helping our clients achieve this balance.

By utilizing advanced CNC technology and SPC, we are able to optimize our production processes to minimize waste, reduce downtime, and streamline operations. This means we can offer competitive pricing for both small and large production runs, ensuring that our clients receive the best value for their investment.

Flexibility in Production

At Radmot, we understand that every client has unique requirements. Whether you need a small batch of parts for a prototype or a large production run for mass manufacturing, we can accommodate your needs. We are capable of producing turned parts starting from 250 units per product batch, ensuring that even small orders are treated with the same level of attention and precision as larger ones.

This flexibility allows us to serve a wide range of industries, including automotive, aerospace, electronics, medical devices, and more. Regardless of your industry or the complexity of your parts, we have the expertise and equipment to deliver.

Certified to IATF 16949 Quality Standards

Quality is at the core of everything we do at Radmot. We are proud to be certified to IATF 16949, the internationally recognized quality management system for the automotive industry. This certification demonstrates our commitment to producing parts that meet the highest standards of quality, reliability, and consistency.

IATF 16949 is more than just a certification; it’s a comprehensive system that ensures that all of our processes are designed to produce high-quality products while continuously improving efficiency. By adhering to these standards, we are able to deliver products that not only meet but exceed our clients’ expectations.

Advanced Technology and Professional Expertise

Radmot’s success wouldn’t be possible without our investment in cutting-edge technology and our team of experienced specialists. We understand that in order to produce high-precision parts, we need to use the best equipment available. That’s why we’ve invested in advanced CNC machines that allow us to produce parts with the utmost precision and consistency.

Our specialists are the backbone of our operation. Each member of our team is highly trained and experienced in CNC machining, ensuring that every part we produce is handled with the highest level of professionalism. From initial design to final inspection, our team is dedicated to ensuring that each order is completed on time and to the exact specifications required by our clients.

Customer-Centric Approach

At Radmot, we believe in putting our customers first. We take the time to understand the unique needs of each client and work closely with them to ensure that their requirements are met. Whether it’s a complex technical challenge or a tight production deadline, we are committed to providing solutions that meet our customers’ needs.

We pride ourselves on our ability to provide customized solutions for each project. By working closely with our clients, we ensure that every aspect of the production process is tailored to their specific requirements. This customer-centric approach has helped us build long-lasting relationships with our clients, who trust us to deliver high-quality results time and time again.

Why Choose Radmot?

Choosing the right manufacturing partner is crucial to the success of any project. When you work with Radmot, you’re choosing a company that is committed to quality, precision, and efficiency. Here are just a few reasons why Radmot should be your preferred choice for CNC turned parts:

- Zero Defects: Our SPC system ensures that every part we produce meets the highest standards of quality, with zero rejects.

- High Precision: We specialize in producing high-precision parts with diameters ranging from 6 mm to 250 mm and lengths up to 680 mm.

- Cost-Effective: Our streamlined production processes allow us to offer competitive pricing without compromising on quality.

- Flexibility: We can handle both small and large production runs, starting from 250 units per product batch.

- Certified Quality: We are certified to IATF 16949, ensuring that our processes meet the highest standards of quality and consistency.

- Customer-Focused: We work closely with our clients to provide customized solutions that meet their unique needs.

Conclusion

At Radmot, our mission is to deliver high-quality CNC turned parts with the utmost precision, efficiency, and cost-effectiveness. With our commitment to statistical process control, advanced technology, and a team of dedicated professionals, we are able to produce parts that meet the highest standards of quality while minimizing waste and maximizing efficiency.